We were recently contracted to inspect a leaking heat exchanger on a 130 foot Westport yacht docked at a local marina. The heat exchanger was part of the hydraulic power unit (HPU) for the ship’s bow thruster system. The HPU consists mainly of a motor, a reservoir tank and a hydraulic pump. These units can generate a tremendous amount of power to drive most any kind of hydraulic ram or motor. They can also generate high temperatures. Most heat exchangers used in the marine industry are water cooled and use a water control valve to regulate the flow of water though the exchanger to keep the hydraulic fluid temperature between 64 and 68 degrees C (147 and 155 degrees F). It is important to make sure the adjustments for the water control valve are set properly to avoid rapid overheating.

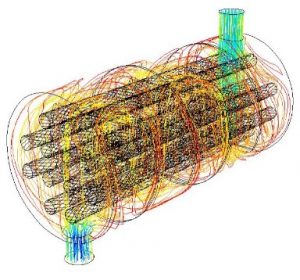

This particular model was a shell and tube design. As its name implies, this type of heat exchanger consists of a shell (a large pressure vessel) with a bundle of tubes inside it. One fluid runs through the tubes, in this case hydraulic oil, and another fluid, water, flows over the tubes (through the shell) to transfer heat between the two fluids. The set of tubes is called a tube bundle and may be composed of several types of tubes.

This particular model was a shell and tube design. As its name implies, this type of heat exchanger consists of a shell (a large pressure vessel) with a bundle of tubes inside it. One fluid runs through the tubes, in this case hydraulic oil, and another fluid, water, flows over the tubes (through the shell) to transfer heat between the two fluids. The set of tubes is called a tube bundle and may be composed of several types of tubes.

Upon inspection, we found that the fittings in the heat exchanger were not properly seated and the sealant used was not sufficient for the job. In order to remedy the problem, we needed to remove the heat exchanger from the HPU and send it out for servicing. In order to do this, we had to disconnect the hard pipe Stauff clamps above the heat exchanger in order to spread the pipes apart to remove the heat exchanger from the bilge. We also disconnected and installed caps and plugs in the hoses connected to the heat exchanger. We resealed the adapters and fitting upon re-installation, connected the hydraulic hoses, installed Stauff clamp supports and tested the unit for leaks.

The heat exchanger is back in operation and helping to ensure that the hydraulic bow thrusters are doing their job helping to maneuver this yacht in tight places.

From time to time, we see some pretty old yachts come into Lauderdale Marine Center as was the case with a 30+ year old Feadship. This old gal was in need of some work to bring her back to her glory days. We were hired to give her hydraulic royal boarding ladder a “face lift.” A hydraulic royal boarding ladder is side mounted typically at mid-ship that retracts using hydraulic folding mechanisms when not in use, leaving your deck free of obstacles.

From time to time, we see some pretty old yachts come into Lauderdale Marine Center as was the case with a 30+ year old Feadship. This old gal was in need of some work to bring her back to her glory days. We were hired to give her hydraulic royal boarding ladder a “face lift.” A hydraulic royal boarding ladder is side mounted typically at mid-ship that retracts using hydraulic folding mechanisms when not in use, leaving your deck free of obstacles.

for our hydraulic technicians to reach and secure the cylinders for removal from the boat. We then rented a boom truck with a 73 foot reach from a local business to remove the luffing cylinders from the yacht and place on our sister company,

for our hydraulic technicians to reach and secure the cylinders for removal from the boat. We then rented a boom truck with a 73 foot reach from a local business to remove the luffing cylinders from the yacht and place on our sister company,

attached to the boom truck crane. Installing the pin on a crane of this size takes balance and a little brute force! Once in place, we released the straps from the boom truck crane and using straps and the chain come-along ratchets, raised the luffing cylinders into place for securing the top to the crane. We then reattached the hydraulic hoses to the yacht’s crane so we could use the boat’s hydraulic power to extend the luffing

attached to the boom truck crane. Installing the pin on a crane of this size takes balance and a little brute force! Once in place, we released the straps from the boom truck crane and using straps and the chain come-along ratchets, raised the luffing cylinders into place for securing the top to the crane. We then reattached the hydraulic hoses to the yacht’s crane so we could use the boat’s hydraulic power to extend the luffing  cylinders for the final pin installation. While this work takes experience and knowledge of the process, performing the task while standing on scaffolding more than 10 feet of the deck adds to the complexity.

cylinders for the final pin installation. While this work takes experience and knowledge of the process, performing the task while standing on scaffolding more than 10 feet of the deck adds to the complexity.

adjust the straps in order to control the unit as it was lifted into the air. Cranes have a very uneven weight distribution and weigh several hundred pounds so without the proper balance applied by the straps and chain come-along, they could twist or slip potentially hitting the deck or the side of the yacht while being lowered to the ground.

adjust the straps in order to control the unit as it was lifted into the air. Cranes have a very uneven weight distribution and weigh several hundred pounds so without the proper balance applied by the straps and chain come-along, they could twist or slip potentially hitting the deck or the side of the yacht while being lowered to the ground.

Continuing the work on the 135’ Broward, we have moved on to work on the NAIAD stabilizer system. While NAIAD does not specify an exact interval for performing a major overhaul, it does recommend replacing the lower seals every three years or 4,000 operating hours. Interim service and maintenance should be performed annually but a major overhaul is highly recommended anytime you find water in the grease beyond the outer shaft seals or signs of grease oozing from the inner seals around the shaft. Once salt water compromises the grease the bearings will start to deteriorate and the grease needs to be replaced

Continuing the work on the 135’ Broward, we have moved on to work on the NAIAD stabilizer system. While NAIAD does not specify an exact interval for performing a major overhaul, it does recommend replacing the lower seals every three years or 4,000 operating hours. Interim service and maintenance should be performed annually but a major overhaul is highly recommended anytime you find water in the grease beyond the outer shaft seals or signs of grease oozing from the inner seals around the shaft. Once salt water compromises the grease the bearings will start to deteriorate and the grease needs to be replaced

We next disassembled and removed the hydraulic power unit (HPU). The HPU consists mainly of a pair of motors, a reservoir tank and a hydraulic pump. These units can generate a tremendous amount of power to drive most any kind of hydraulic ram. Hydraulic Power Units are based on Pascal’s law of physics, drawing their power from ratios of area and pressure. In this case, the HPU takes the commands from the helm to push the hydraulic rods in the right direction to steer the yacht. A failure of the hydraulic steering system at sea or just about anywhere could prove to be catastrophic.

We next disassembled and removed the hydraulic power unit (HPU). The HPU consists mainly of a pair of motors, a reservoir tank and a hydraulic pump. These units can generate a tremendous amount of power to drive most any kind of hydraulic ram. Hydraulic Power Units are based on Pascal’s law of physics, drawing their power from ratios of area and pressure. In this case, the HPU takes the commands from the helm to push the hydraulic rods in the right direction to steer the yacht. A failure of the hydraulic steering system at sea or just about anywhere could prove to be catastrophic. motors out for testing and tested all of the pumps to ensure they were in good working order. We also made all

motors out for testing and tested all of the pumps to ensure they were in good working order. We also made all