Fine Scores In Rods

A customer walked into High Seas Hydraulics with three leaking Quantum Stabilizer cylinders from a 150 foot Trinity motor yacht. Upon close inspection, it was determined that there were fine scores or scratches in the hydraulic rods that were causing the fluid to bypass the seals. These scratches could not be repaired or polished out so new hydraulic rods would need to be installed.

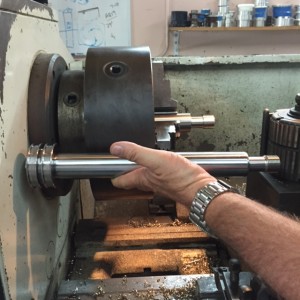

Raw material for rods

That is when our hydraulic teams turned to our sister company, machine shop Straight Line Marine. Through our procurement department at High Seas, we were able to source raw materials to fabricate new hydraulic rods within a day.

The Straight Line Marine machinist went to work and crafted new rods to exact specifications including intricate thread machining.

Finished rod

The ability to bring the stabilizer cylinders back to top working order with new hydraulic rods fabricated on-site in our machine shop saved this motor yacht’s owner and captain both time and money and was completed from a one-stop company.

upon installation re-routed many of them to alleviate the pinching problems. We have the ability to make hydraulic hoses in-house, on-site at Lauderdale Marine center up to 1-1/4 inches in diameter and stock common hoses and fittings.

upon installation re-routed many of them to alleviate the pinching problems. We have the ability to make hydraulic hoses in-house, on-site at Lauderdale Marine center up to 1-1/4 inches in diameter and stock common hoses and fittings.