Bow and stern thrusters are critical components on any mega yacht. Not only do they increase the maneuverability of large vessels but also play an important part in the safety of other boats around the docks particularly in larger vessels is tight spaces. Most of these systems are driven by hydraulics on vessel from 80-180 feet but others are driven by electric motors.

Bow and stern thrusters are critical components on any mega yacht. Not only do they increase the maneuverability of large vessels but also play an important part in the safety of other boats around the docks particularly in larger vessels is tight spaces. Most of these systems are driven by hydraulics on vessel from 80-180 feet but others are driven by electric motors.

When hauled it is a good idea to drain the gear oil out of the leg to check for water or metal. If no water is present, add fresh gear oil and the service is done. New seals can easily be added depending on the brand and model of thruster. If salt water is present, the gear leg can be removed for disassembly and assessment on gears and bearings. More often, we find oil in the tunnel beneath the propeller a few days after haul-out that indicates leaking shaft seals that would need to be replaced. While we typically do not change out zincs unless requested, zincs for bow and stern thrusters are specific to the brand of thrusters so that would be included in the maintenance service.

We were recently called on to service a bow thruster on one of our repeat clients where the propellers complete broke apart due to improper installation. We were able to secure new props and rebuild the thrusters to “like new” condition.

Because your bow and stern thrusters are in constant contact with sea water, we recommend that you inspect and service them twice a year to ensure that your yachting experience in close quarters and safe and stress free.

Our hydraulics team was recently contacted by a welding contractor at Lauderdale Marine Center to remove a PTO pump off a 150’ Palmer Johnson’s main hydraulics system so they could gain access to the ship to perform their work. What started as a fairly routine job quickly turned into something much more. The splines on the unit had seized, taking what would have been roughly a half day of work to several days.

Our hydraulics team was recently contacted by a welding contractor at Lauderdale Marine Center to remove a PTO pump off a 150’ Palmer Johnson’s main hydraulics system so they could gain access to the ship to perform their work. What started as a fairly routine job quickly turned into something much more. The splines on the unit had seized, taking what would have been roughly a half day of work to several days. And we will be there with Lauderdale Marine Center in Booth #640. Stop by and visit with us. We will have our technicians and mechanics there from both High Seas Hydraulics and High Seas Yacht Service to answer any questions you may have on running gear vibrations or hydraulic systems. Hope to see you at the Show!

And we will be there with Lauderdale Marine Center in Booth #640. Stop by and visit with us. We will have our technicians and mechanics there from both High Seas Hydraulics and High Seas Yacht Service to answer any questions you may have on running gear vibrations or hydraulic systems. Hope to see you at the Show! We then moved on to work on the entire hydraulic central system where we performed a full hydraulic fluid flush, cleaned and pressure tested the heat exchangers and changed all the filters.

We then moved on to work on the entire hydraulic central system where we performed a full hydraulic fluid flush, cleaned and pressure tested the heat exchangers and changed all the filters.

It is not uncommon to find Vosper stabilizers in many older yachts and ships. What is uncommon these days is to find a company that specializes in the repair, service and maintenance of the older units. VT Motion, the company that supplied Vosper stabilizers, was acquired by Naiad in 2009 and absorbed into its Naiad Maritime Group.

It is not uncommon to find Vosper stabilizers in many older yachts and ships. What is uncommon these days is to find a company that specializes in the repair, service and maintenance of the older units. VT Motion, the company that supplied Vosper stabilizers, was acquired by Naiad in 2009 and absorbed into its Naiad Maritime Group. Removal of the pump was extremely difficult due to corrosion between the pump shaft splines and the coupling. The corrosion was due to exposure to saltwater and normal wear and tear. In the marine business, the internal and external splines that make up the coupling usually reside on different pieces of equipment supplied by different vendors. The SAE Involute spline standards are the most commonly used for shaft diameters between ½” and 2”. The tolerances are loose enough to insure multi-vendor interchangeability while still providing torque transmission significantly higher than a keyed coupling. The tight fit avoids any lash and excessive wear in the splines over the life of the pump. There are many benefits in using spline shafts in place of a keyed shaft for this application. The spline connection offers a load distribution which is equal along the teeth sides enabling both to rotate together. Consequently, this load produces a longer fatigue life compared to the keyway drive.

Removal of the pump was extremely difficult due to corrosion between the pump shaft splines and the coupling. The corrosion was due to exposure to saltwater and normal wear and tear. In the marine business, the internal and external splines that make up the coupling usually reside on different pieces of equipment supplied by different vendors. The SAE Involute spline standards are the most commonly used for shaft diameters between ½” and 2”. The tolerances are loose enough to insure multi-vendor interchangeability while still providing torque transmission significantly higher than a keyed coupling. The tight fit avoids any lash and excessive wear in the splines over the life of the pump. There are many benefits in using spline shafts in place of a keyed shaft for this application. The spline connection offers a load distribution which is equal along the teeth sides enabling both to rotate together. Consequently, this load produces a longer fatigue life compared to the keyway drive. Our running gear mechanics inspected the shafts to ensure they were straight and aligned and replaced the bearings and seals. Normal wear and tear associated with running the vessel and prolonged exposure to salt water makes this task a necessary evil for properly maintaining the boat. As seen in the adjacent photo, there was a visible gap where the cutlass bearing adjoined to the shaft.

Our running gear mechanics inspected the shafts to ensure they were straight and aligned and replaced the bearings and seals. Normal wear and tear associated with running the vessel and prolonged exposure to salt water makes this task a necessary evil for properly maintaining the boat. As seen in the adjacent photo, there was a visible gap where the cutlass bearing adjoined to the shaft. recommends changing the lower stabilizer fin seals every couple of years but at least every six years depending on use. The components on the stabilizer are constantly working except is absolute calm seas, so the wear and tear can be considerable. After dropping the fins, we proceeded to change out the old lower stabilizer fin seals with new ones, check the hoses and cylinders, then reassembling the units.

recommends changing the lower stabilizer fin seals every couple of years but at least every six years depending on use. The components on the stabilizer are constantly working except is absolute calm seas, so the wear and tear can be considerable. After dropping the fins, we proceeded to change out the old lower stabilizer fin seals with new ones, check the hoses and cylinders, then reassembling the units. To round out the work on this Westport, we did an overhaul on the bow thruster, single Maxwell windlass, the boat’s heat exchangers and the hydraulic steering system which was slow to respond.

To round out the work on this Westport, we did an overhaul on the bow thruster, single Maxwell windlass, the boat’s heat exchangers and the hydraulic steering system which was slow to respond. When a 118-foot yacht was hauled out at Lauderdale Marine Center for a full refit including paint, our hydraulics team was called upon to refurbish some of the vessels hydraulic parts including its deck crane and side boarding ladders. After a thorough inspection, we removed the units and rebuilt them to “like new condition.” We stripped the units for paint and replaced all hydraulic hoses, cylinders and hardware. Once the other work is completed on the yacht, we will re-install the side boarding ladders and crane. The “new” side boarding ladders and deck crane will complement the look of the refitted vessel and provide years of service for future voyages.

When a 118-foot yacht was hauled out at Lauderdale Marine Center for a full refit including paint, our hydraulics team was called upon to refurbish some of the vessels hydraulic parts including its deck crane and side boarding ladders. After a thorough inspection, we removed the units and rebuilt them to “like new condition.” We stripped the units for paint and replaced all hydraulic hoses, cylinders and hardware. Once the other work is completed on the yacht, we will re-install the side boarding ladders and crane. The “new” side boarding ladders and deck crane will complement the look of the refitted vessel and provide years of service for future voyages.

Every system on a mega yacht is important to the overall comfort and safety of the vessel and vessel’s using hydraulics are no exception. So how often should a hydraulic system, like those used for the steering, stabilizers, bow thrusters or windlass operations be flushed? To be on the safe side, a sample of the hydraulic fluids should be tested every six to 12 months or whenever the system is opened and potentially exposed to outside contaminants, you suspect that water may have infiltrated the tank or metal particles are found in the oil.

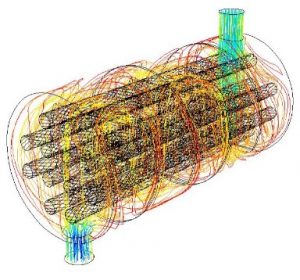

Every system on a mega yacht is important to the overall comfort and safety of the vessel and vessel’s using hydraulics are no exception. So how often should a hydraulic system, like those used for the steering, stabilizers, bow thrusters or windlass operations be flushed? To be on the safe side, a sample of the hydraulic fluids should be tested every six to 12 months or whenever the system is opened and potentially exposed to outside contaminants, you suspect that water may have infiltrated the tank or metal particles are found in the oil. This particular model was a shell and tube design. As its name implies, this type of heat exchanger consists of a shell (a large

This particular model was a shell and tube design. As its name implies, this type of heat exchanger consists of a shell (a large