BCS Trim Tab

Trim tabs are an essential component for any yacht. They improve performance, helping to increase speed, reduce pounding and on smaller boats offset prop torque. They help the vessel run more efficiently, reducing fuel consumption and engine laboring and eliminate “squatting.” But more importantly, they increase safety by improving visibility and handling along with reducing wake size and hull stress.

However, years of use and prolonged exposure to salt water can take a toll on their ability to function properly as was the case with an 85’ Ferretti that was hauled at Lauderdale Marine Center.

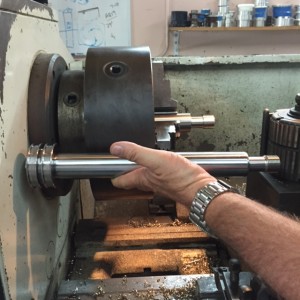

That is when our hydraulics team was called in to work on the BCS hydraulic trim tabs. Upon close inspection, we found that two of the four trim tab cylinders were corroded beyond repair and needed to be replaced. Because of manufacturer’s long lead time, we decided that we would machine new rods, barrels and re-build the cylinders in-house, using our machine shop, Straight Line Marine.

Corrosion in Barrel

The corrosion we found on the inside of the barrel was caused by salt water intrusion as a result of failed seals. Once the components were machined, we were ready to assemble the new hydraulic trim tab cylinders and re-install in the yacht. Unlike common trim tab cylinders, the BCS model does not use hydraulic hoses to distribute the hydraulic fluid to operate the trim tabs. The fluid is dispersed through a small pin hole in the transom bracket assembly. A clever design that eliminates hose failure external to the transom. However this creates a tricky install.

Pin Hole

The pin has multiple O-rings and requires a special touch to avoid pinching during installation. Great care must be taken in the removal of the old hydraulic trim tab cylinders and the re-installation of the new ones. Damage to the assembly as a result of scratching or scoring the unit would cause them to leak and render the trim tab cylinders useless.

We see these types of nuisances all the time. It takes a team of highly experienced hydraulics technicians to properly diagnosis the problems and take the appropriate actions to correct them.

From time to time, we see some pretty old yachts come into Lauderdale Marine Center as was the case with a 30+ year old Feadship. This old gal was in need of some work to bring her back to her glory days. We were hired to give her hydraulic royal boarding ladder a “face lift.” A hydraulic royal boarding ladder is side mounted typically at mid-ship that retracts using hydraulic folding mechanisms when not in use, leaving your deck free of obstacles.

From time to time, we see some pretty old yachts come into Lauderdale Marine Center as was the case with a 30+ year old Feadship. This old gal was in need of some work to bring her back to her glory days. We were hired to give her hydraulic royal boarding ladder a “face lift.” A hydraulic royal boarding ladder is side mounted typically at mid-ship that retracts using hydraulic folding mechanisms when not in use, leaving your deck free of obstacles.

for our hydraulic technicians to reach and secure the cylinders for removal from the boat. We then rented a boom truck with a 73 foot reach from a local business to remove the luffing cylinders from the yacht and place on our sister company,

for our hydraulic technicians to reach and secure the cylinders for removal from the boat. We then rented a boom truck with a 73 foot reach from a local business to remove the luffing cylinders from the yacht and place on our sister company,

attached to the boom truck crane. Installing the pin on a crane of this size takes balance and a little brute force! Once in place, we released the straps from the boom truck crane and using straps and the chain come-along ratchets, raised the luffing cylinders into place for securing the top to the crane. We then reattached the hydraulic hoses to the yacht’s crane so we could use the boat’s hydraulic power to extend the luffing

attached to the boom truck crane. Installing the pin on a crane of this size takes balance and a little brute force! Once in place, we released the straps from the boom truck crane and using straps and the chain come-along ratchets, raised the luffing cylinders into place for securing the top to the crane. We then reattached the hydraulic hoses to the yacht’s crane so we could use the boat’s hydraulic power to extend the luffing  cylinders for the final pin installation. While this work takes experience and knowledge of the process, performing the task while standing on scaffolding more than 10 feet of the deck adds to the complexity.

cylinders for the final pin installation. While this work takes experience and knowledge of the process, performing the task while standing on scaffolding more than 10 feet of the deck adds to the complexity. Continuing the work on the 135’ Broward, we have moved on to work on the NAIAD stabilizer system. While NAIAD does not specify an exact interval for performing a major overhaul, it does recommend replacing the lower seals every three years or 4,000 operating hours. Interim service and maintenance should be performed annually but a major overhaul is highly recommended anytime you find water in the grease beyond the outer shaft seals or signs of grease oozing from the inner seals around the shaft. Once salt water compromises the grease the bearings will start to deteriorate and the grease needs to be replaced

Continuing the work on the 135’ Broward, we have moved on to work on the NAIAD stabilizer system. While NAIAD does not specify an exact interval for performing a major overhaul, it does recommend replacing the lower seals every three years or 4,000 operating hours. Interim service and maintenance should be performed annually but a major overhaul is highly recommended anytime you find water in the grease beyond the outer shaft seals or signs of grease oozing from the inner seals around the shaft. Once salt water compromises the grease the bearings will start to deteriorate and the grease needs to be replaced

We next disassembled and removed the hydraulic power unit (HPU). The HPU consists mainly of a pair of motors, a reservoir tank and a hydraulic pump. These units can generate a tremendous amount of power to drive most any kind of hydraulic ram. Hydraulic Power Units are based on Pascal’s law of physics, drawing their power from ratios of area and pressure. In this case, the HPU takes the commands from the helm to push the hydraulic rods in the right direction to steer the yacht. A failure of the hydraulic steering system at sea or just about anywhere could prove to be catastrophic.

We next disassembled and removed the hydraulic power unit (HPU). The HPU consists mainly of a pair of motors, a reservoir tank and a hydraulic pump. These units can generate a tremendous amount of power to drive most any kind of hydraulic ram. Hydraulic Power Units are based on Pascal’s law of physics, drawing their power from ratios of area and pressure. In this case, the HPU takes the commands from the helm to push the hydraulic rods in the right direction to steer the yacht. A failure of the hydraulic steering system at sea or just about anywhere could prove to be catastrophic. motors out for testing and tested all of the pumps to ensure they were in good working order. We also made all

motors out for testing and tested all of the pumps to ensure they were in good working order. We also made all

The boat had a Naiad stabilizer and hydraulic system. During our inspection of the stabilizers, we found evidence of grease passing through the inner seal housing.

The boat had a Naiad stabilizer and hydraulic system. During our inspection of the stabilizers, we found evidence of grease passing through the inner seal housing.