Bow and stern thrusters are critical components on any mega yacht. Not only do they increase the maneuverability of large vessels but also play an important part in the safety of other boats around the docks particularly in larger vessels is tight spaces. Most of these systems are driven by hydraulics on vessel from 80-180 feet but others are driven by electric motors.

Bow and stern thrusters are critical components on any mega yacht. Not only do they increase the maneuverability of large vessels but also play an important part in the safety of other boats around the docks particularly in larger vessels is tight spaces. Most of these systems are driven by hydraulics on vessel from 80-180 feet but others are driven by electric motors.

When hauled it is a good idea to drain the gear oil out of the leg to check for water or metal. If no water is present, add fresh gear oil and the service is done. New seals can easily be added depending on the brand and model of thruster. If salt water is present, the gear leg can be removed for disassembly and assessment on gears and bearings. More often, we find oil in the tunnel beneath the propeller a few days after haul-out that indicates leaking shaft seals that would need to be replaced. While we typically do not change out zincs unless requested, zincs for bow and stern thrusters are specific to the brand of thrusters so that would be included in the maintenance service.

We were recently called on to service a bow thruster on one of our repeat clients where the propellers complete broke apart due to improper installation. We were able to secure new props and rebuild the thrusters to “like new” condition.

Because your bow and stern thrusters are in constant contact with sea water, we recommend that you inspect and service them twice a year to ensure that your yachting experience in close quarters and safe and stress free.

Our running gear mechanics inspected the shafts to ensure they were straight and aligned and replaced the bearings and seals. Normal wear and tear associated with running the vessel and prolonged exposure to salt water makes this task a necessary evil for properly maintaining the boat. As seen in the adjacent photo, there was a visible gap where the cutlass bearing adjoined to the shaft.

Our running gear mechanics inspected the shafts to ensure they were straight and aligned and replaced the bearings and seals. Normal wear and tear associated with running the vessel and prolonged exposure to salt water makes this task a necessary evil for properly maintaining the boat. As seen in the adjacent photo, there was a visible gap where the cutlass bearing adjoined to the shaft. recommends changing the lower stabilizer fin seals every couple of years but at least every six years depending on use. The components on the stabilizer are constantly working except is absolute calm seas, so the wear and tear can be considerable. After dropping the fins, we proceeded to change out the old lower stabilizer fin seals with new ones, check the hoses and cylinders, then reassembling the units.

recommends changing the lower stabilizer fin seals every couple of years but at least every six years depending on use. The components on the stabilizer are constantly working except is absolute calm seas, so the wear and tear can be considerable. After dropping the fins, we proceeded to change out the old lower stabilizer fin seals with new ones, check the hoses and cylinders, then reassembling the units. To round out the work on this Westport, we did an overhaul on the bow thruster, single Maxwell windlass, the boat’s heat exchangers and the hydraulic steering system which was slow to respond.

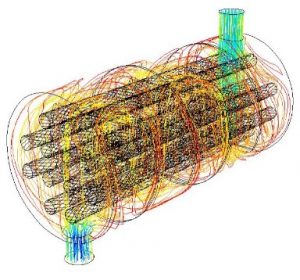

To round out the work on this Westport, we did an overhaul on the bow thruster, single Maxwell windlass, the boat’s heat exchangers and the hydraulic steering system which was slow to respond. This particular model was a shell and tube design. As its name implies, this type of heat exchanger consists of a shell (a large

This particular model was a shell and tube design. As its name implies, this type of heat exchanger consists of a shell (a large